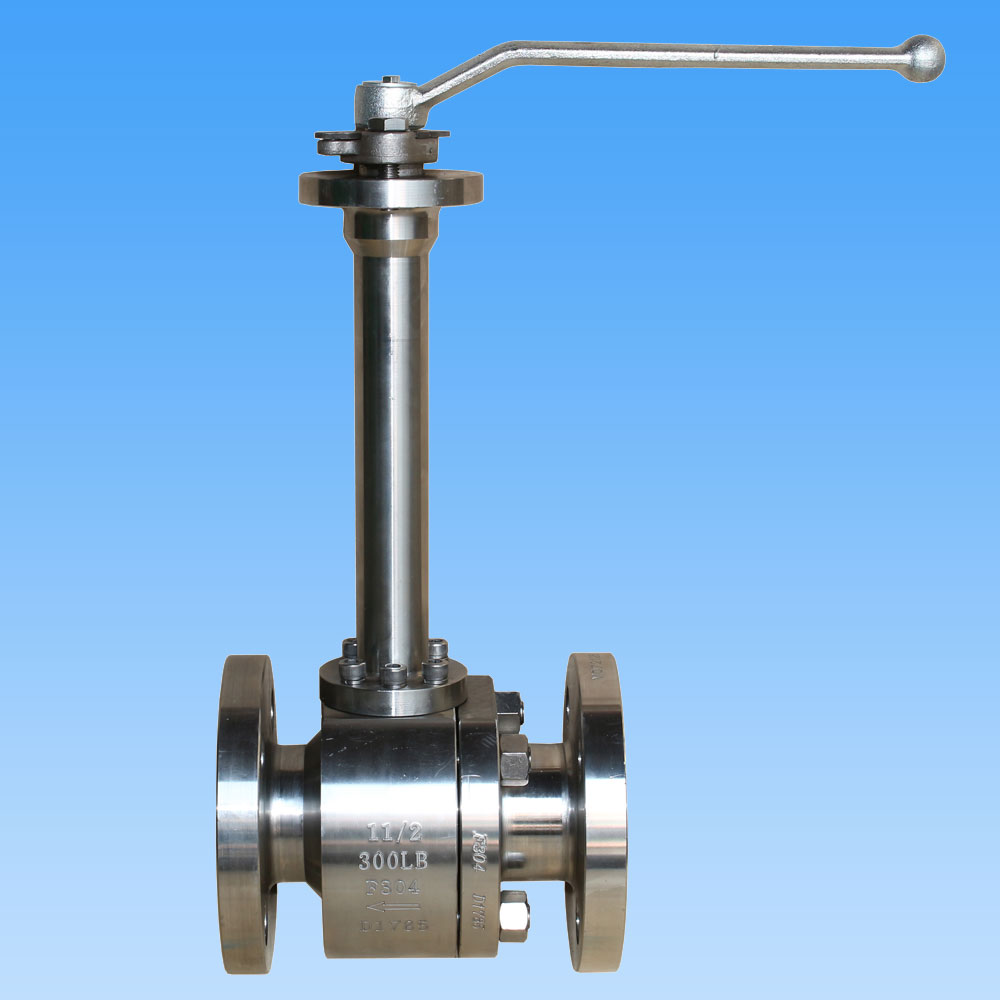

Cryogenic Forged Ball Valve

Send Inquiry

LYV as a professional high quality cryogenic forged Cryogenic Forged Ball Valve manufacturer in China, you can rest assured to our factory that the cryogenic forged ball valves be offered according to strict design standard API 6D&ASME B16.34 and cryogenic testing procedures, the limit temperature could be as low as -196℃.

Cryogenic forged ball valves are used for low temperature working condition, especially for some hazard media, such as liquidized nature gas. Our company has been experienced in the design, manufacturing, inspection and testing of cryogenic ball valves.

Design & Testing International Standard

Design Standard : BS EN ISO 17292 (BS 5351) / ASME B 16.34 /API 6D

Inspection & Testing Standard : API 598/ API 6D

Fire Safe Testing Standard : API 607/API 6FA

Flange To Flange Length : ANSI B 16.10 -Short pattern/ Long pattern

End Connection : Flanged End to ANSI B 16.5, Butt Weld ends, Stock Weld ends.

Manufacturer Size and Pressure Range:

NPS 1/2” to 48” (for ANSI Class 150LB)

NPS 1/2” to 48” (for ANSI Class 300LB)

NPS 1/2” to 48” (for ANSI Class 600LB)

NPS 1/2” to 36” (for ANSI Class 900LB)

NPS 1/2” to 24” (for ANSI Class 1500LB)

NPS 1/2” to 12” (for ANSI Class 2500LB)

or

DN15 to DN1200 (for PN0.6Mpa, 1.6Mpa, PN2.0Mpa, PN2.5Mpa)

DN15 to DN1200 (for PN4.0Mpa, PN5.0Mpa)

DN15 to DN1200 (for PN6.3Mpa, PN10.0Mpa)

DN15 to DN900 (for PN15.0Mpa)

DN15 to DN600 (for PN25.0Mpa)

Extended bonnet design to reliability of the stem packing & sealing, suitable for the working temperature -196℃.

Pipe Bore: Full Bore (FB)/ Reduce Bore(RB)

Construction Body: End Entry

Bonnet/Cover type: Bolted Bonnet/Extended Bonnet

Seat Type: Soft type/ Hardseal Metal Type

Flow Directional: Uni-Directional/Bi-Directional

Service Medium: Oil, Water, gas , etc

Service: SOUR, ISO 15156/ NACE MR0175

Feature: Fire Safety design

Anti-Static Design

Blow-out Proof Stem

Valve Operation: Manual Lever / Worm-Gear /Actuator Operated/ Pneumatic Actuator / Electrical Actuator

MOC (Bill of Material – BOM) :

Body &Bonnet: ASTM A350 LF2 /LF3 (Low temp. carbon steel)

: ASTM A182 F304/ F316(SS 304 / SS 316) (Stainless Steel)

:ASTM A182 F304L/ F316L / CF 3M (SS 304L / SS 316L) (Stainless Steel)

Solid Ball : ASTM A350 LF2/ LF3 (Low temp. carbon steel)

: ASTM A 182 F304 / F316 (SS 304 / SS 316)

: ASTM A 182 F304L / F316L (SS 304L / SS 316L)

Note: Harseal Metal Seat type Ball surface treatment: ENP, HCR, WC, welding Ni60/ Ni55

Stem :ASTM A182 F304 / F316 / F304L / F316L

Ball Seat & Body Seal : Carbon Filled PTFE – CFT

: Grafoil – Graphite Ring

Gland Packing : Carbon Filled PTFE – CFT

: Grafoil – Graphite Ring