Why Choose a Ball Valve for Your Industrial and Commercial Applications?

When it comes to fluid control, selecting the right valve is essential for safety, efficiency, and longevity of your pipeline system. Among various valve types, the Ball Valve stands out as one of the most widely used and trusted solutions in industries such as oil and gas, chemical, water treatment, and HVAC systems. With its simple design, reliable sealing performance, and long service life, it has become the preferred choice for both engineers and purchasing managers worldwide.

At Zhejiang Liangyi Valve Co.,Ltd., we have been dedicated to manufacturing precision-engineered ball valves that meet international standards. With decades of expertise, advanced production equipment, and strict quality inspection, our products deliver superior performance across demanding industrial conditions.

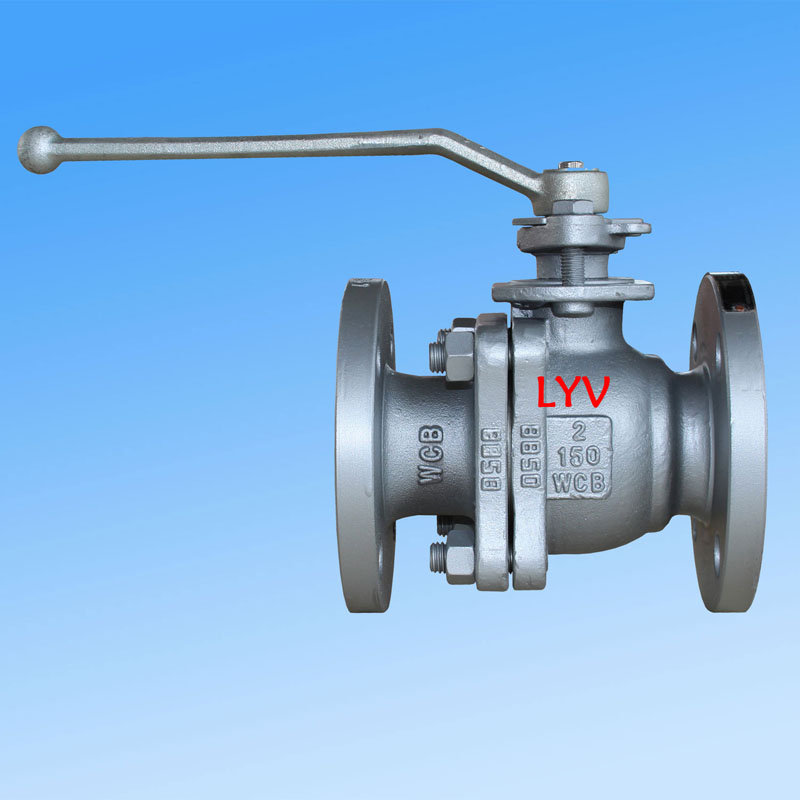

What Is a Ball Valve and How Does It Work?

A ball valve is a quarter-turn valve that uses a spherical disc (the "ball") to control the flow of liquid or gas. The ball has a hole (called a port) through the middle. When the valve handle is turned 90 degrees, the port either aligns with the pipeline (allowing flow) or is perpendicular (blocking flow).

This simple yet effective mechanism ensures:

-

Fast operation: Open or close with just a quarter turn.

-

Excellent sealing: Prevents leakage under high pressure.

-

Low maintenance: Robust construction with fewer moving parts.

Key Advantages of Using Ball Valves

-

Tight Shutoff – Prevents leaks even under high pressure and temperature.

-

Durability – Built to last with minimal wear and tear.

-

Versatility – Suitable for liquids, gases, and even corrosive fluids.

-

Easy Operation – Quick quarter-turn control.

-

Wide Range of Sizes – From small pipelines to heavy industrial applications.

Product Parameters of Our Ball Valves

At Zhejiang Liangyi Valve Co.,Ltd., every Ball Valve is engineered with precision. Below is a simplified parameter table showcasing our product specifications:

| Parameter | Specification Range | Notes |

|---|---|---|

| Size Range | 1/2" – 24" | Customized sizes available |

| Pressure Rating | PN10 – PN420 / Class 150 – 2500 | Suitable for low to ultra-high pressure |

| Body Material | Carbon Steel, Stainless Steel, Alloy | Optional materials for corrosive fluids |

| Ball & Stem Material | Stainless Steel, Chrome Plated Steel | Ensures anti-corrosion and durability |

| Connection Type | Flanged, Threaded, Welded | Adaptable to different piping systems |

| Seat Material | PTFE, RPTFE, Metal Seated | Flexible for different temperature needs |

| Temperature Range | -46°C to +450°C | Designed for both cryogenic & high temp |

| Operation Type | Manual, Pneumatic, Electric | Full automation support available |

Why Are Our Ball Valves Important in Industrial Use?

Choosing the right valve can save significant maintenance costs and ensure continuous operation. For industries dealing with corrosive fluids, high-pressure pipelines, or strict safety regulations, our Ball Valve is an essential component.

-

Oil & Gas Industry – For safe flow control in pipelines.

-

Chemical Processing – Resistant to corrosive substances.

-

Water Supply & Treatment – Reliable sealing for clean and wastewater systems.

-

HVAC Systems – Easy control of heating and cooling fluids.

-

Marine and Offshore – Designed for harsh environments.

Typical Applications

-

Pipeline shutoff and isolation

-

Emergency shutoff systems

-

Flow regulation in industrial plants

-

High-pressure process lines

-

Steam and thermal fluid systems

Ball Valve FAQ – Common Questions Answered

Q1: What is the difference between a Ball Valve and a Gate Valve?

A ball valve uses a rotating spherical ball with a bore to start or stop flow, requiring only a quarter-turn to operate. A gate valve uses a sliding gate mechanism and usually requires multiple turns. Ball valves are faster, more compact, and provide tighter sealing, making them ideal for quick shutoff applications.

Q2: Can Ball Valves be used for throttling applications?

Yes, ball valves can be used for throttling, but it depends on the valve design. Standard ball valves are primarily designed for on/off control, but V-port or trunnion-mounted designs can provide precise flow regulation. For critical throttling, globe valves are sometimes recommended, but advanced ball valves handle this effectively in many industries.

Q3: How do I maintain a Ball Valve for longer service life?

Maintenance is minimal compared to other valve types. Regular checks should include:

-

Inspecting for leakage around seals.

-

Ensuring the stem and ball rotate smoothly.

-

Lubricating moving parts when necessary.

-

Replacing seats and seals in case of wear.

With proper installation and periodic checks, our ball valves can last for many years under continuous use.

Why Choose Zhejiang Liangyi Valve Co.,Ltd.?

-

20+ Years of Expertise – A trusted name in valve manufacturing.

-

Strict Quality Standards – ISO, API, and CE certified products.

-

Customization – Tailor-made solutions to fit unique pipeline needs.

-

Global Clients – Serving customers across Europe, America, and Asia.

-

Reliable Service – Professional after-sales and technical support.

We don't just sell valves; we deliver reliability, safety, and efficiency to every project.

Conclusion

When selecting valves for your next project, reliability and performance are non-negotiable. A Ball Valve offers unmatched durability, tight shutoff, and ease of use. With Zhejiang Liangyi Valve Co.,Ltd., you gain a partner committed to providing world-class valve solutions that keep your operations running smoothly.

For inquiries, specifications, or to request a quotation, please contact Zhejiang Liangyi Valve Co.,Ltd. today. Our technical team is ready to support your project with the right ball valve solution.